Products Buss

Buss is the global leader in kneaders for demanding compounding applications. As the original manufacturer of the rotating and oscillating screw shaft techno.

Used Buss KoKneader Extruder, Model TCS 10016

To begin with, the co-kneader is, from a design point of view, a continuously op- erating single-screw extruder. Its operat- ing principle, however, clearly distin- guishes it from traditional designs. Its screw spiral is interrupted by two to four The One that Shears, Splits, and Folds Material

Buss PR200 11LD KoKneader

DOI: 10.1080/03602559808006935 Corpus ID: 135635724; Development of The Modern Buss Kneader and The Study of Its Flow and Mixing Mechanisms @article{White1998DevelopmentOT, title={Development of The Modern Buss Kneader and The Study of Its Flow and Mixing Mechanisms}, author={James L White and Min Young Lyu}, journal={Polymer-plastics Technology and Engineering}, year={1998}, volume={37.

75 Jahre Buss Ein Dreiviertel Jahrhundert

Co-Kneader - Buss MKS 30. The Buss Kneader is a unique compounding extruder. Its most outstanding feature is a special operating principle in which the screw shaft performs a synchronous back-and-forth movement in the axial direction with each revolution. This sinusoidal motion sequence is made possible by a special gear.

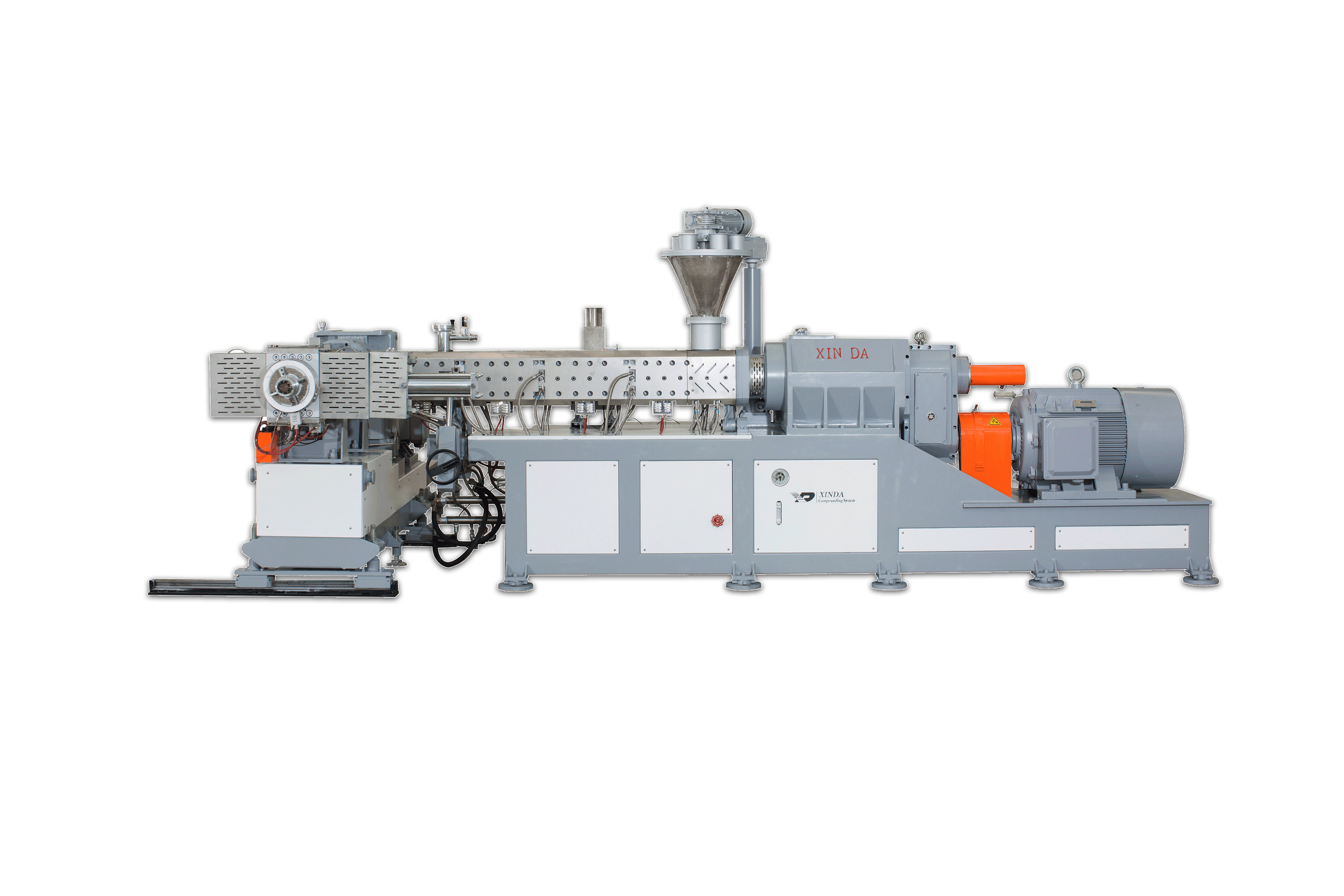

CoKneader XINDA

The Buss kneader is a suitable reactor for bakelite powder molding production and has found various applications in industry all over the world [1]. Nevertheless, no publication about kneader scale-up and process design on real industrial process can be found in the available literature.

BUSS Kneader Technology YouTube

Features and benefits of Buss Kneader technology: Extremely short processing length, uniform shearing effect without temperature peaks, significantly lower product temperatures, precise temperature control. The Buss Academy is a competence center where Buss compounding expertise is applied and expanded.

Used Buss Kneader System, Type 96EV10C 2004 Qu

The Co-Kneader, a low-shear rotating and reciprocating single-screw extruder is designed for shear and temperature sensitive compounds. The flights on the screw are interrupted and interact with three rows of stationary kneading pins located in the barrel wall.

Compounding Systems Mixing and Kneading Technologies Buss AG

Our Compounding Technology : The extrusion potential is made up of various technologies: single-screw extruders, twin-screw extruders, and buss co-kneaders. This atypical diversity of extruders allows Polytechs to create a wide range of compounds and masterbatches from various polymer supports. One of our special features is the extrusion and.

Buss Type CoKneader /Single Screw Plastic Granulator Extruder for PE

At K 2022 Buss will show its new compact, user-friendly Compeo Lab compounder for throughputs of 50 to 100 kg/hr for development, process optimization and small production runs. Bus says it offers all the advantages of the large Compeo co-kneaders, including the combination of two-, three- and four-flight screw elements, and provides precise.

Used Buss KoKneader, Model KR100 Stock 43212001 YouTube

The co-kneader (s. Title figure) is a single-screw extruder for compounding and modifying polymers and other substances. Although co-kneaders are specialists for the processing of highly filled plastics, rubbers, and TPE (thermoplastic elastomers), they keep ex-panding into one new application after another.

Buss Type CoKneader /Single Screw Plastic Granules Extruder for PE/PVC

Features and benefits of Buss' MX Kneader series for cable compounds and masterbatch, as presented during K 2007.

Used Buss KoKneader Extruder, Model TCS 10016

Careers BUSS offers unique compounding systems based on the BUSS Kneader technology for mixing and kneading that set standards for heat and shear sensitive applications.

BUSS Kneader Technology YouTube

The development of the modern modular Buss Kneader from its origins is described. We also summarize experimental studies of the characteristics of this machine. Finally, we review efforts at simulation of flow and design analyses for the Buss Kneader. Reprints and Corporate Permissions.

Products Buss

14:16 On 20 August 1945, graduate engineer Heinz List filed a patent for the principle of the continuous kneader. Convinced by the concept, Buss AG inaugurated the first kneader test centre in 1948 and delivered the first compounding systems for PVC and polystyrene in 1950, by which time List had become technical director. Expand

Co Kneader, Buss Co Kneader, Buss Kneader Xinda

BUSS AG - Working Principle Co-Kneader - YouTube © 2023 Google LLC BUSS is a global leader in compounding solutions for demanding applications. As the original manufacturer of the Buss.

.jpg)

Buss Kneader System, Type 96EV10C 2004, 2007 Plastic Machinery

The excellent mixing capabilities of the Buss kneader can be attributed to its unique operating principle: simultaneous rotation and axial oscillation of the screw shaft. As the original.